There was a time when human beings used to stay in caves and river banks. They used to cover their body with leaves and animal skins. With the advancement of civilisation, human beings have developed fabrics from natural fibres and in the contemporary age man-made fibres.

Now fabric/cloth is among the three basic needs of every human being along with food and shelter. As described in Maslow’s need hierarchy Roti(food), Kapra(Cloth), Makan(Shelter) are the three basic needs.

Table of Contents

Fibre to yarn and yarn to fabric

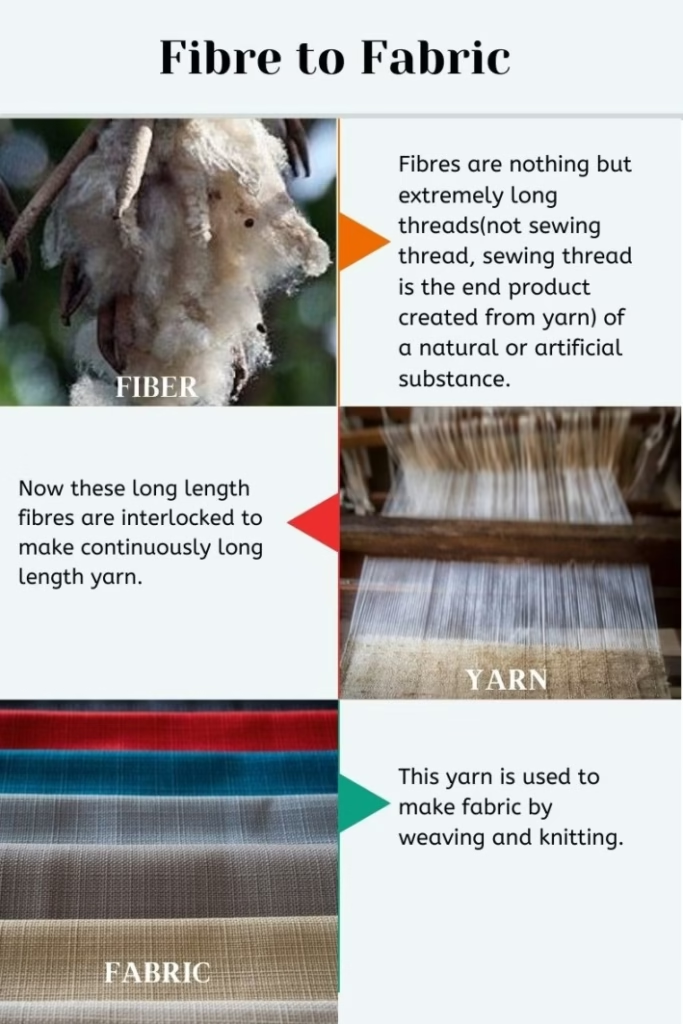

To know what is fabric, first, we need to understand what yarn is and to know what is yarn we need to understand what is fibre.

What is Fibre?

Fibres are nothing but extremely long threads(not sewing thread, sewing thread is the end product created from yarn) of a natural or artificial substance.

What is yarn and how fabric is manufactured from yarn?

Now these long-length fibres are interlocked to make continuously long-length yarn. This yarn is used to make fabric by weaving and knitting.

So Yarns are defined as long and continuous fibres that are twisted or interlocked. They are used to make fabrics by knitting, weaving, sewing, etc. Once fibres are extracted from their sources, they are very thin and entangled. Yarns are made up of thin fibre strands called fibres. The process of making yarn from fibres is known as spinning. During this process, a mass of cotton or wool is pulled out and twisted. This brings the fibres together to form yarn.

Types of Fibres

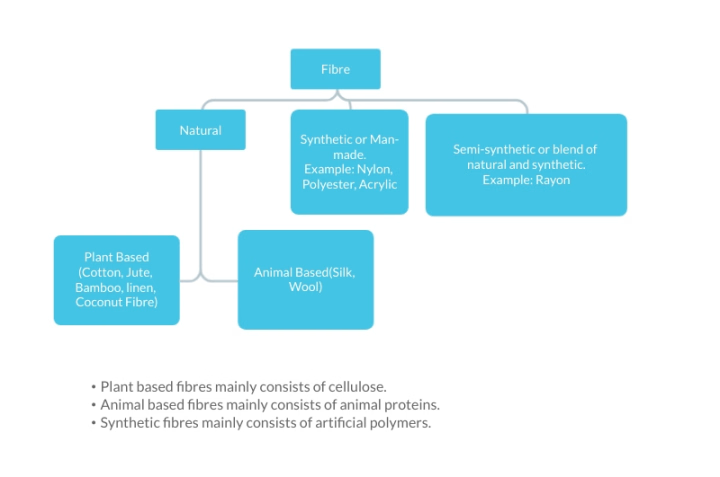

You can classify this into 2 basic types

- Natural Fibre

- Man-made fibres

Natural fibres can be divided into two subdivisions

- Plant-based fibres

- Animal-based fibres

Man-made fibres can be divided into 2 subdivisions

- Regenerated Fibres(Semi-synthetic fibre or a blend of a man-made and synthetic fibre)

- Synthetic Fibres

The classification of fabrics can also be determined based on the types of fibers they are made from.

Natural Fibre

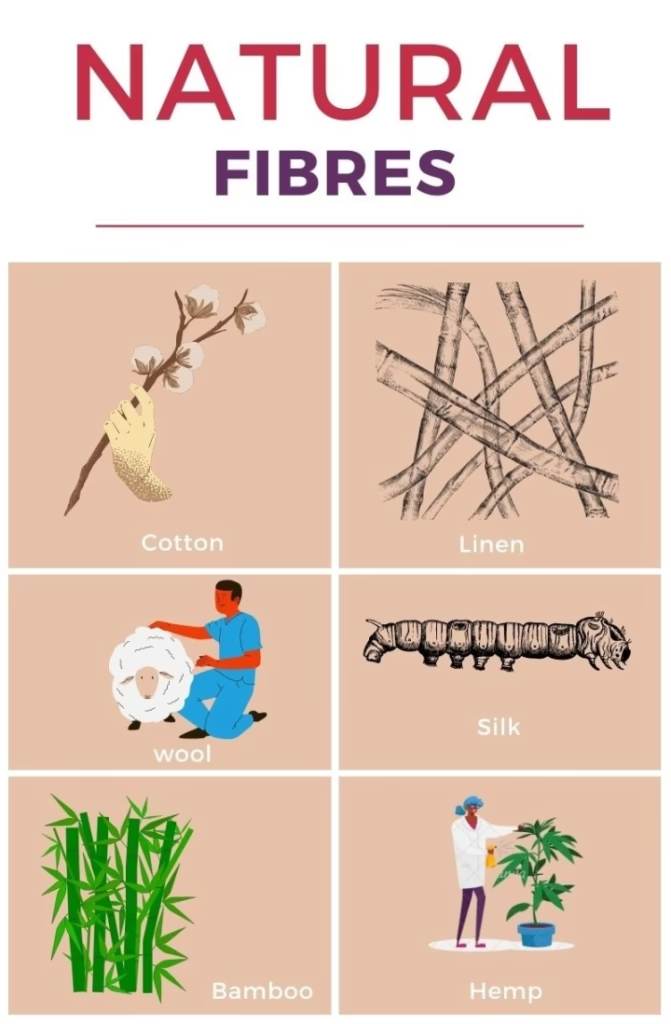

Fibres obtained from natural sources are called natural fibre. These can be classified into two sub divisions based on the source.

Types of Natural Fibres

- Plant fibres

- Animal fibres

Plant Fibres

Fibres obtained from plants are known as plant-based fibres. Plant fibers are generally composed of cellulose. The following are the types of plant fibres.

a) Cotton

Cotton fabrics are generally used in those countries which have hot climates. Because cotton is lightweight and good absorbent.

Cotton is extracted from cotton bolls or pods. The boll is the rounded mature fruit of the cotton plant. It is made up of separate compartments which are called locks, in which cotton seeds and lint grow. These open at harvest time. The cotton is ready to be picked when the bolls crack open and the fluffy white cotton is exposed.

Ginning: The cotton bolls consist of cotton and seeds. The process of separating the cotton from the seeds is called ginning. It also helps in removing impurities like dust, small stones, wooden particles etc.

Spinning: After the cotton is separated from the seeds the fibre is ready for the spinning process. The process of converting the fibre to yarn is called spinning. fibre is the large threads that come out after the ginning process. These large threads are not interlocked. After the spinning process, these are interlocked and become extra large continuous threads called yarn.

In India Charkha was widely used for this spinning process and it is a symbol of freedom movement after popularized by Mahatma Gandhi.

Weaving: After creating the yarn from the spinning process the next step is to make the fabric from this yarn. The individual yarn threads joined together to make a fabric. This process of joining the yarn threads are called weaving.

b) Jute

The jute fibres are extracted from the stem and ribbon (outer skin) of the jute plant. The fibres are extracted by immersing them in slow-running water for a long time by the process known as retting. Once retting is over, stripping begins to make long jute fibres. Mostly, jute fibres are used for making handlooms, bags, carpets, etc.

c) Flax

Stems of flax plants are widely used to extract fibres, popularly known as linen, used extensively in the textile industry.

d) Coir

Coir, also known as coconut fibre, is a natural fibre extracted from the outer husk of coconut and used in manufacturing floor mats, doormats, mattresses, brushes, etc.

e) Bamboo

What is the more intrinsic use of bamboo? It is the recent production of bamboo into an ultra-soft and comfortable eco-friendly fabric. How can a material that has the tensile strength of Steel be transformed into an ultra-soft fabric? The answer lies in the incredibly unique manufacturing process. It begins with the harvest of mature bamboo that is nearly 2 years old. The bamboo is then taken and chopped into pieces resulting in piles of raw bamboo chips. Those bamboo chips are then soaked in a solution which has been approved by the global organic textile standard. This solution breaks down the bamboo fibre extracting the bamboo pulp that is then dried in parchment-like sheets. Once thoroughly dried these sheets are ready to be ground and spun into a soft fluffy material referred to as bamboo fibre. The bamboo fibre is then separated and spun into thread which is used to create yarn for weaving. the resultant fabric is twice as soft as compared to luxury fabrics like silk. It can be used to make products like t-shirts or luxurious king-size bed sheets. Bamboo fabric-made bed sheets are a truly comfortable eco-friendly way to enjoy a good night’s sleep.

Animal Fibres

Fibres obtained from Animals are known as Animal fibres. They are mostly extracted from the skin, furs, and hairs of animals that mostly consist of proteins. The following are types of animal fibres.

a) Silk Fibre

Silk fabric comes from silk fibre and silk fibre comes from animals which are silkworms,

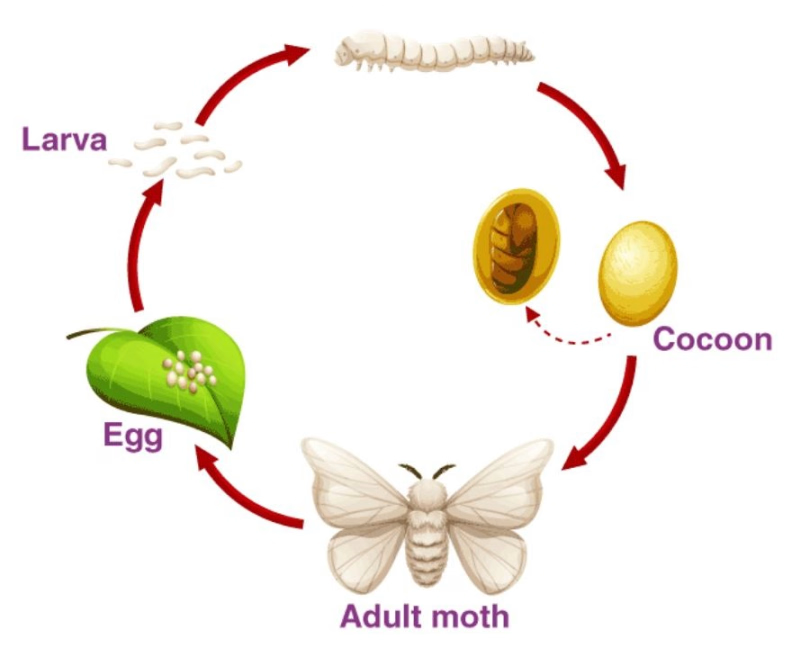

Stage 1: Egg

A female moth produces eggs on tree leaves, however, it produces eggs only on mulberry leaves, not on all tree leaves this stage is called the egg stage.

Stage 2: Silkworm

The next stage is the larvae stage: consuming the mulberry leaves this egg developed into larvae, this stage called INSTAR(Phase between the two moulting processes of the insect larvae, The period from the larvae to the moulting is called INSTAR.

Stage 3: Cocoon

In this stage, silkworms spin a protective cocoon around itself. It is the size of a small cotton ball and is made of a single thread of silk.

Stage 4: Pupa

The pupa stage is a motionless stage. In this stage, people kill the pupa by plunging the cocoon into boiling water and unwinding the silk thread.

Stage 5: Moth

In this stage, the pupa changes into an adult moth. The female moth lays eggs after mating and thus the life cycle of the silkworm begins again.

Processing of silk

Extracting silk from the cocoon is known as the processing of silk. Silk is separated from the cocoon by exposing it to sunlight. After the reeling of silk is done, the process of unwinding silk from a cocoon takes place. The silk thread is then bleached. The silk fibre is then spun into silk threads.

To learn about the Rich History of Silk in India, From Ancient Times to the Modern Day, click on the link below.

b) Wool

Wool is obtained from the hairs of sheep, goats or camels. They are made from shearing sheep that are sorted on the basis of quality and are later prepared for spinning. In this process, the wool fibres are spun into long strands that are then woven into a fabric. Since wool is a great thermal insulator, they are extensively used for making woollen clothes such as sweaters, shawls, etc.

So basically Wool is the textile fibre obtained from sheep and other animals, including cashmere and mohair from goats.

Cashmere wool, usually simply known as cashmere, is a fibre obtained from cashmere goats, pashmina goats, and some other breeds of goats. It has been used to make yarn, textiles and clothing for hundreds of years. Cashmere is closely associated with the Kashmir shawl, the word “cashmere” deriving from an anglicisation of Kashmir when the Kashmir shawl reached Europe in the 19th century. Both the soft undercoat and the guard hairs may be used; the softer hair is reserved for textiles, while the coarse guard hair is used for brushes and other non-apparel purposes.

A number of countries produce cashmere and have improved processing techniques over the years, but China and Mongolia are two of the leading producers as of 2019. Afghanistan is ranked third.

Mohair is a fabric or yarn made from the hair of the Angora goat. Both durable and resilient, mohair is notable for its high lustre and sheen and is often used in fibre blends to add these qualities to a textile. Mohair takes dye exceptionally well. It feels warm in winter as it has excellent insulating properties, while its moisture-wicking properties allow it to remain cool in summer. It is durable, naturally elastic, flame-resistant and crease-resistant. It is considered a luxury fibre, like cashmere, angora can be more expensive than most sheep’s wool.

Man-made or synthetic fibre

Synthetic or man-made fibres are basically artificially made polymers. Though we don’t want to deep dive into organic chemistry but just to understand at a high level that polymers are nothing but very large molecules. A polymer consists of a number of monomers. Just for example, sugars are monomers and carbohydrates are polymers. Though sugar does not have any significance here, the example is given for a basic understanding of monomers. Examples of natural polymers are cellulose, carbohydrate, protein etc. These are the basic substances that exist in living bodies. Silk, wool etc whatever we have learned in the above section are natural polymers. Similarly, synthetic fabrics are also polymers but these are made artificially. So synthetic fibres are made artificially by linking monomers, forming a polymer by the process known as polymerisation. They are made by chemical synthesis using various reagents and chemicals. They are mostly synthesised from a raw material called Petrochemicals. Some types of synthetic fibres used in the textile industry are elastane, nylon, acrylic, polyester and P.U. leather. Following are a few types of synthetic fibres explained.

Acrylic

Acrylic may also be called a cheaper version of wool. They are not actually wool, but they are Polyacrylonitrile. Acrylic is used for making sweaters, blankets, etc.

Nylon

Nylon is the name of a family of synthetic polymers that are commonly used to make a variety of different types of apparel and consumer goods. Unlike other organic or semi-synthetic fibres, nylon fibres are entirely synthetic, which means that they have no basis in organic material.

Polyester

Polyester is a synthetic polymer made up of repeating units of ester groups to form polymers. Polyester is mixed with cotton to form poly-cot fabrics; wool is combined to form poly-wool. polyethene is another form of polyester used for making bottles, utensils, and many other substances.

Regenerated Fibres

Rayon

Rayon is a synthetic fibre made artificially from cellulose extracted from wood pulp and other agricultural products. Thus, rayon is a semi-synthetic fibre, as it is derived from natural fibre. It is also called artificial silk due to its thin fibres and lightweight. It is used in manufacturing clothes, carpets, curtains, blankets, etc.

Some comparisons between Natural Fibre and man-made Fibre

- Natural fibres are biodegradable, while synthetic fibres are non-biodegradable.

- Natural fibres are more porous, breathable and suitable absorbent than synthetic fibres, which makes them more comfortable to wear for those with sensitive skin or for allergic people.

- Natural fibres are harder to care for as compared to synthetic fibres that remain smooth and crisp even after washing. It means natural fibres need more maintenance.

- Natural fibres are less durable as compared to synthetic fibres.

- Synthetic fibres are cheaper than natural fibres as they are synthesised in laboratories using chemicals.

- Instead of natural fibres, synthetic fibres are used to make raincoats and jackets as they are waterproof.

If you wish to delve deeper into fabrics, click the button below to explore various types of fabrics derived from plant-based or cellulosic fibres. Discover their properties, uses, and historical significance.

Click the button below to explore various types of fabrics derived from animal-based protein fibres. Discover their properties, uses, and historical significance.

To learn about various types of man-made fibres, including regenerated fibres and fabrics, as well as synthetic fibres, click on the link below. Gain insights into the world of man-made textiles.

If you want to join our diploma course in fashion design click on the below button.

We dedicate countless hours to crafting study materials for fashion design students through this blog. Our posts encompass various topics from the fashion design syllabus. If you have any suggestions, questions, or doubts, please feel free to share them in the comment section below.